News

新闻资讯

- 我国精密模具市场前景可期!

- 如何谨慎的修理模具,主要的修复方法有哪些?

- 精密注塑制品出现披锋该如何调整?

- 当下中国模具行业市场现状及发展方向,值得借鉴

- 2021年中国汽车注塑模具市场现状及发展趋势预测分析

contact us

mobile phone:18020299888

Telephone:0510-85436666

mailbox:651706814@qq.com

Address bus:No. 29-2, Lu Ou Road, Hudai Industrial Park, Binhu District, Wuxi City

Industry news

How to repair the mold carefully? What are the main repair methods?

- author:管理员

- Release time:2022-08-05

- click:233

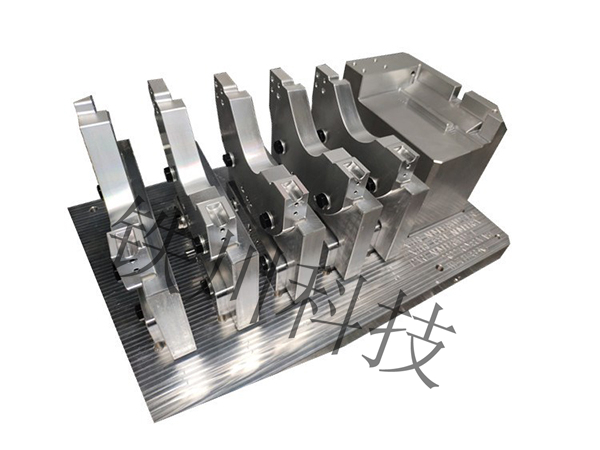

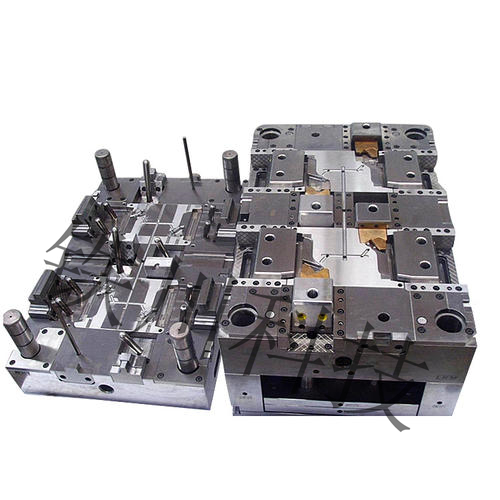

Mold plays an extremely important role in modern industry. Its quality directly determines the quality of products. Improving the service life and accuracy of the mold and shortening the manufacturing cycle of the mold are the technical problems that many enterprises need to solve urgently, but in the process of using the mold, there are often bad conditions such as collapse, deformation, wear, and even fracture that need to be repaired.

Repair the mold should be careful, do not act rashly if you are not sure. The reason is that once the mold conditions are changed, it can no longer be greatly transformed and restored to the original state, and it is not sure that random repair will get worse and worse. Therefore, it is necessary to repair the mold, but it also needs to use the correct way. There are many ways to repair molds, such as EDM process, argon arc welding repair, laser surfacing technology, brush plating method and so on.

Argon arc welding repair

The arc burning between the continuously fed welding wire and the workpiece is used as the heat source, and the gas shielded arc emitted by the torch nozzle is used for welding. At present, argon arc welding is a common method, which can be applied to most major metals, including carbon steel and alloy steel. Melt inert gas shielded welding is suitable for stainless steel, aluminum, magnesium, copper, titanium, zirconium and nickel alloys. Due to its low price, it is widely used in mold repair welding. However, due to the disadvantages of large welding heat affected area and large welding spots, laser welding has been gradually replaced in precision mold repair.

Brush plating repair

Brush plating technology adopts a special DC power supply equipment, and the positive pole of the power supply is connected to the plating pen as the anode during brush plating; The negative pole of the power supply is connected to the workpiece as the cathode during brush plating. The plating pen usually uses high-purity fine graphite block as the anode material, and the graphite block is wrapped with cotton and wear-resistant polyester cotton sleeve.

When working, the power supply assembly is adjusted to the appropriate voltage, and the plating pen soaked in the plating solution is in contact with the surface of the repaired workpiece at a certain relative speed. The metal ions in the plating solution diffuse to the surface of the workpiece under the action of the electric field force, and the electrons on the surface are reduced to metal atoms, so that these metal atoms deposit and crystallize to form a coating, That is to obtain the required uniform deposition layer on the working surface of the repaired plastic mold cavity.

Laser surfacing repair

Laser welding is a kind of welding that uses laser beam formed by focusing high-power coherent monochromatic photon flow as heat source. This welding method usually includes continuous power laser welding and pulse power laser welding. The advantage of laser welding is that it does not need to be carried out in vacuum, but the disadvantage is that the penetration is not as strong as electron beam welding. The energy control during laser welding can realize the welding of precision devices. It can be applied to many metals, especially to solve the welding of some difficult to weld metals and dissimilar metals. At present, it has been widely used in mold repair.

客服QQ

客服QQ