News

新闻资讯

- 我国精密模具市场前景可期!

- 如何谨慎的修理模具,主要的修复方法有哪些?

- 精密注塑制品出现披锋该如何调整?

- 当下中国模具行业市场现状及发展方向,值得借鉴

- 2021年中国汽车注塑模具市场现状及发展趋势预测分析

联系我们

手机:18020299888

电话:0510-85436666

邮箱:651706814@qq.com

地址:No. 29-2, Lu Ou Road, Hudai Industrial Park, Binhu District, Wuxi City

Industry news

Mold precautions

- 作者:管理员

- 发布时间:2022-08-05

- 点击:211

1、 Don't just focus on product design and ignore plastic mold manufacturing.

When developing products or trial production of new products, some users often focus on product development and development at the initial stage, ignoring the communication with plastic mold manufacturers. After the preliminary determination of the product design scheme, there are two advantages to contact the mold manufacturer in advance:

1. It can ensure that the designed product has a good forming process and will not modify the finalized design because the parts are difficult to process.

2. The mold manufacturer can make design preparations in advance to prevent careless consideration in a hurry from affecting the construction period.

3. To make high-quality plastic molds, only the supply and demand sides cooperate closely, can we reduce the cost and shorten the cycle.

2、 Don't just look at the price, but consider the quality and cycle.

1. There are many kinds of molds, which can be roughly divided into ten categories. According to the different requirements of part materials, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, economy and so on, different types of dies are selected for forming.

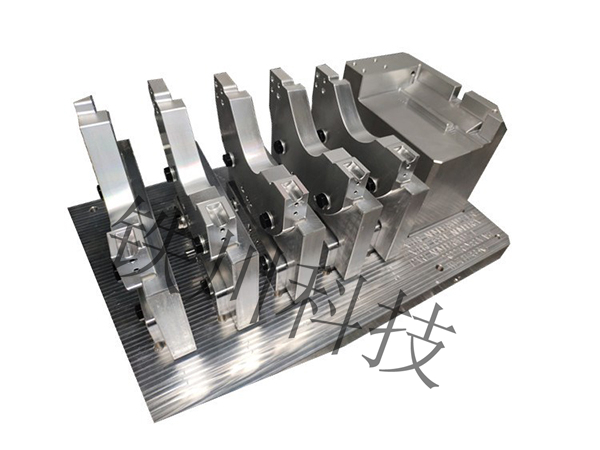

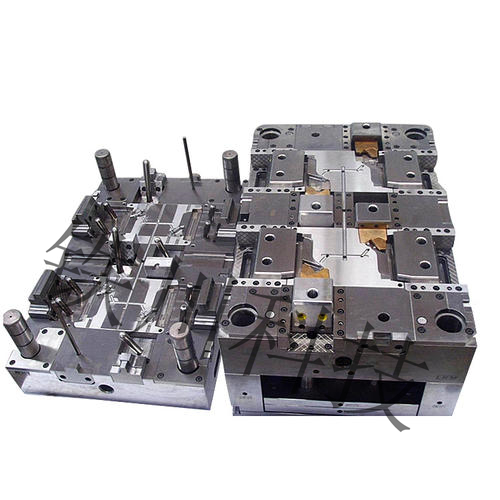

2. The mold with high precision needs to be processed by high-precision CNC machine tools, and the mold material and forming process have strict requirements. It also needs to use CAD / CAE / CAM mold technology to design and analyze.

3. Because some parts have special requirements during molding, the mold also needs to use advanced processes such as hot runner, gas assisted molding, nitrogen cylinder and so on.

4. The manufacturer should have CNC, EDM, wire cutting machine tools and CNC profiling milling equipment, high-precision grinding machines, high-precision three coordinate measuring instruments, computer design and related software.

5. Generally, large stamping dies (such as auto cover dies) should consider whether the machine tool has blank holder mechanism, even edge lubricant, multi station progressive, etc. In addition to stamping tonnage, punching times, feeding devices, machine tools and die protection devices should also be considered.

6. The manufacturing methods and processes of the above molds are not possessed and mastered by every enterprise. When choosing a cooperative manufacturer, we must understand its processing ability. We should not only look at the hardware equipment, but also combine the management level, processing experience and technical strength.

7. For the same set of molds, there is sometimes a big gap between the quotations of different manufacturers. You should not pay more than the mold value, nor less than the mold cost. Mold manufacturers, like you, should make reasonable profits in their business. Ordering a set of moulds with a much lower quotation will be the beginning of trouble. Users must start from their own requirements and measure.

3、 Avoid multi head cooperation, and try to integrate plastic mold production and product processing.

1. With qualified molds (qualified test pieces), batch qualified products may not be produced. This is mainly related to the selection of machining machine tools, forming process (forming temperature, forming time, etc.) and the technical quality of operators.

2. With good molds, we should also have good forming and processing. We should cooperate in a one-stop way and try to avoid multi head cooperation. If the conditions are not met, it is necessary to select one party to be responsible, and be sure to write clearly at the same time of the agreement.

客服QQ

客服QQ