News

新闻资讯

- 我国精密模具市场前景可期!

- 如何谨慎的修理模具,主要的修复方法有哪些?

- 精密注塑制品出现披锋该如何调整?

- 当下中国模具行业市场现状及发展方向,值得借鉴

- 2021年中国汽车注塑模具市场现状及发展趋势预测分析

联系我们

手机:18020299888

电话:0510-85436666

邮箱:651706814@qq.com

地址:No. 29-2, Lu Ou Road, Hudai Industrial Park, Binhu District, Wuxi City

Common problem

The current market situation and development direction of China's mold industry are worth learning from

- 作者:管理员

- 发布时间:2022-08-05

- 点击:172

China's mold industry developed relatively late, and the modern mold industry did not start until the late 1970s. However, after years of efforts, China's mold manufacturing industry has established a mold industry system, including mold technology research and development institutions, mold production and supply systems, through the introduction of more mature design and manufacturing technology and independent innovation from internationally industrialized countries and regions, The scale and technical level of mold industry have made great progress.

1、 Mold industry overview:

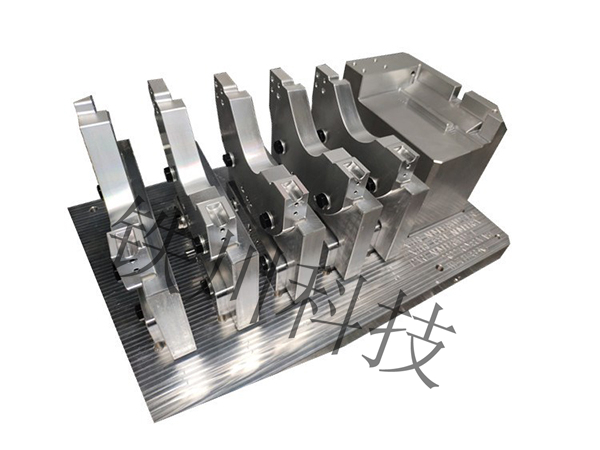

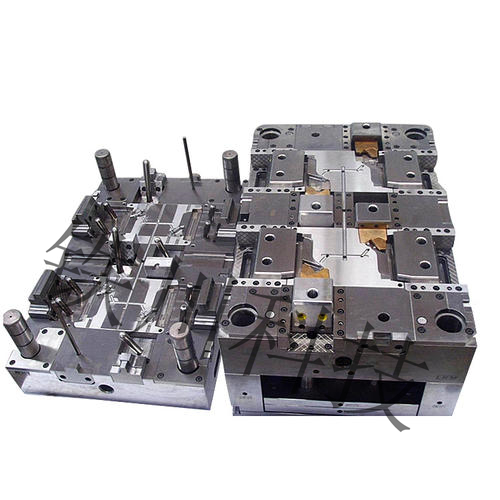

As the foundation of modern industry, mold technology has been widely used in automotive, energy, machinery and other fields. In electronics, automobiles, televisions, electrical appliances, meters, instruments, household appliances, communications and other products, 60% - 80% of the parts rely on mold molding.

The high precision, high complexity, high consistency, high productivity and low energy consumption of parts produced with molds are unmatched by other processing and manufacturing methods.

The mold industry is also the "benefit amplifier" of the manufacturing industry. The value of the final product produced by the mold is often dozens of times or hundreds of times the value of the mold itself.

The level of mold industry has become an important symbol to measure the level of a country's manufacturing industry, and it is also one of the important guarantees for a country to maintain international competitiveness.

Technology leads the development of industrial technology and promotes the continuous innovation of the mold industry. After more than half a century of development, China's mold industry has been greatly improved, and the development speed is very rapid. In general, the development of mold manufacturing in China has experienced the following four stages:

2、 Current market situation of China's mold industry:

According to the data, from 2017 to 2019, China's mold production showed an annual growth trend. In 2019, China's mold production reached 27.337 million sets, a year-on-year increase of 49.28%, and the production in the first quarter of 2020 was 2.6741 million sets.

From the perspective of mold output, we are now a big mold manufacturer in the world. Although China's mold industry has made great progress, domestic mold manufacturing enterprises are uneven, and even many are private small workshops. Even if there are professional mold factories, the scale is not large.

It will still be our goal for a long time to strive for new technologies and innovative ideas as we continue to move towards becoming a world mold power.

Among the total sales of molds in China, injection molds and stamping molds are the main areas of the mold market, and plastic molds account for the largest proportion, accounting for about 45%; Stamping dies account for about 37%; The proportion of casting mold is only 9%; Other types of molds account for about 9%.

The top six major mold manufacturers in the world are China, the United States, Japan, Germany, South Korea and Italy. Among the molds, automobile related molds account for the largest proportion, about 34%, and household electronics 28%. Other industries are as follows:

Judging from the data, China's mold industry has great prospects for development in the future.

Due to the development limitations of technology, the competition in the mold manufacturing industry is intensifying, and the mergers and acquisitions and capital operations among large mold manufacturing enterprises are becoming increasingly frequent. More and more mold manufacturing enterprises feel the importance of upgrading and transformation. In this broad prospect, the development of intelligent mold has become the primary goal of mold enterprise upgrading.

Compared with traditional molds, intelligent molds have obvious advantages such as high technical content, high added value of products, long service life, wide application range and large market space. They are also important weights for enterprises to compete. The state also began to support independent products and gradually reduce imports, which brought new development opportunities to domestic brands.

3、 Analysis on the development trend of China's mold industry:

1. High precision

With the continuous learning in recent years, China's mold industry has developed rapidly and developed a number of companies specializing in high-precision mold manufacturing. More and more enterprises also realize that the accuracy of mold size is the most important factor in manufacturing high-precision, high-quality and high-tech products.

To make high-precision molds, there are only two important factors: equipment and talents, but at present, China still has a certain distance from foreign countries in the most precise field. After all, for China, manufacturing is the embodiment of a country's comprehensive national strength, so the country has attached great importance to it, and it will surpass it in the near future.

2. Automation and intelligent chemical plants are the trend

Automation and intellectualization are the guarantee to improve efficiency. With the popularization of various automatic equipment (mainly manipulator) that cooperate with mold production, and the improvement of intellectualization of standard parts inside the mold (mainly hot runner), the efficiency of mold production is getting higher and higher, and will develop towards a higher and better realm.

The future development should be that there are only a few people in a factory, and the rest are all machines and computers. In the future, there will be only three kinds of "people": managers, technicians and robots.

3. New type

With the technological innovation, the new type makes many of the original impossibilities become possible, and many of the original complex and tortuous ways become very simple. These are new opportunities and challenges for the mold industry. Specifically, they are opportunities and challenges for mold designers.

Whether we can master the new mold design and manufacturing technology is the lifeblood of a mold enterprise. Mastering the high and new technology of mould requires deep design and manufacturing background, and these high and new technologies have also become the resources for the company to build brands and win more high-quality customers.

The current war is a war of technology without gunpowder smoke. The price of shopping is not as good as that of shopping. As long as we innovate in technology and achieve new mold, even if the price is higher, there will be a large number of customers, which is the power of the brand. Mold is always an industry that wins with technology and quality.

4. Amalgamation

Integration refers to the high integration of product development and mold.

This trend is also inevitable. This change is a change that can affect the manufacturing mode better than the replacement of the omnipotent mold master by the assembly line.

In short, mold designer and product R & D are integrated into a new post, a new post that can be responsible for the whole product from appearance to organization, then to mold, to mold processing, mold production, product assembly, and become the absolute core of the manufacturing industry.

Conclusion: to survive and develop in this era, these directions are worth considering.

1. Accelerate the transformation to meet the market demand;

2. Give full play to the advantages of large-scale clusters to keep warm;

3. Enhance brand value, increase R & D investment, and strengthen patent layout.

客服QQ

客服QQ